Metalcam Group differentiates itself from other companies for being able to provide its customers with the most effective technical & metallurgic solutions by choosing the right materials and creating the optimal production cycle. Ever since its creation, Metalcam Group has contributed to very important international projects in different industrial fields, by co-operating with some of the leading companies in the Oil & Gas, Energy, Shipbuilding and Mechanical Industries, Hot work tool steel, etc.

Metalcam Group is the everyday choice of hundreds of customers all around the world who value its huge production capacity as well as the highest expertise in the technical & metallurgic fields, its worldwide sales network, commitment, quality and care in looking after its customers.

Metalcam Group is one of the most valued Italian companies of high quality steel forgings.

Metalcam Group stands out for its integrated production process combining in one single site planning, steel making, forging, heat treatment and machining of a wide range of products for a variety of industrial applications. Metalcam is the most reliable partner who is able to satisfy each customer’s specific needs always ensuring the highest quality of its finished products.

The numbers

Share capital

5.060.000 €

Production site

75.000 square meters, of which 45.000 indoors

Team

250 employees

Production Capacity

70.000 tons of steel p.a. and 40.000 tons of forged products p.a.

Product range

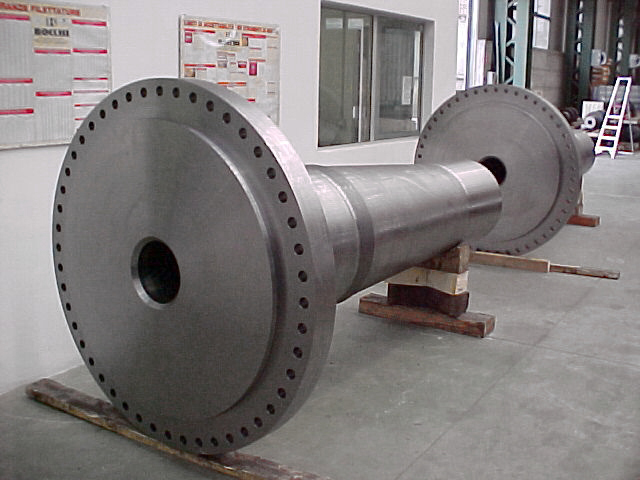

Ingots weighing from 5 up to 48 tons, forged products from 100 Kg up to 35 tons, 16 m maximum length, 2,5 m maximum diameter

Markets

Metalcam can supply medium to large size steel forgings that satisfy all customers’ needs and for all the following market’s applications:

- Mechanical Industry (rolls & axles for cement factories, shafts, pinion gears and wheels for reduction units)

- Oil & Gas / Petrochemical Industry

- Energy (shafts for wind mill generators, thermoelectric & hydraulics turbines, gas & steam turbines)

- Shipbuilding

- Hot work tools steel

- Raw material for forges and rolling mills (ingots, rough shapes, bars)

Products

Metalcam internally controls each step of the production cycle: starting from the product engineering right through to the making of the finished part, from planning to delivery, from custom made heats to forging, heat treatment and machining activities.

Inspection and certification are carried out in accordance with the current international legislation.

The raw material is supplied in a wide range of quality products: special carbon steels, alloyed steels, stainless steels, all complying with customers’ technical specifications and international regulations.

Steel forgings can be supplied in raw, rough or final machined condition.

Main products (finished parts from 100 Kg up to 35tons):

Mechanical Industry

- Pistons, cylinders mandrels & crosspieces for presses

- Mandrels and cylinders for the production of tubes

- Segments, mandrels & rolls for rolling mills

- Sleeves, adapters

- Shafts, pinion gears & wheels for reduction units

- Bushes for paper mills

- Rolls & axles for cement factories

- Bushes and pistons for hydraulic cylinders

- Shells for the production of centrifugated pipes

- Rings

Energy

- Pelton runners for hydro power plants

- Compressor discs and shafts for gas turbines

- Compressor shafts for steam turbines

- Rotors & generator shafts

- Valve bodies for nuclear power plants

- Shafts for wind mill generators

- Rings

Oil & Gas and Petrochemical Industry

- Valve bodies for oil rigs

- Wing Block

- BOPs

- Valve bodies and other parts for Wellheads (including subsea)

- Structural parts for platforms

- Stress joints for riser systems

- Bushes, flanges, valves and other parts for oil refineries and chemical plants,(heat exchangers)

- Shells

- Virole

- Pipeline connectors

- Pipeline tubes

- Rings

Shipbuilding

- Propeller shafts, rudder shafts and shafts for stabilizers

- Bearing shafts

- Bushes

- Cylinder and piston heads

- Rings

Hot work tool steel

- Outer mantles

- Liners

- Extrusion stems